I. Purpose & Scope

To provide an overview of hazard communication within the workplace.

II. Definitions

HazCom – The OSHA Hazard Communication Standard, HCS, 29 CFR 1910.1200.

III. Policy

NOTE: This written hazard communication program shall be developed, implemented, and maintained at each workplace that describes how labels & other forms of warning, safety data sheets, & employee information will be met.

A. General Policy of MGE Underground, Inc.

- The purpose of this notice is to inform you that MGE Underground, Inc. is complying with the OSHA Hazard Communication Standard, Title 29 Code of Federal Regulations 1910.1200, by the following actions:

- Compiling a hazardous chemicals list.

- By using SDS’s.

- By ensuring that containers are labeled.

- By providing you, the employee with training.

- This program applies to all work operations in MGE Underground, Inc. where you may be exposed to hazardous substances under normal working conditions or during an emergency situation.

- The Responsible Safety Officer is the program coordinator who has overall responsibility for the program. The Responsible Safety Officer will review and update the program, as necessary.

- Under this program, you will be informed of the following items:

- The Hazard Communications Standard.

- The hazardous properties of chemicals with which you work.

- Safe handling procedures.

- Measures to take to protect yourself from these chemicals.

- Hazards associated with non-routine tasks.

- Hazards associated with unlabeled containers.

B. List of Hazardous Chemicals

- A list of the hazardous substances known to be present using an identity that is referenced on the appropriate safety data sheet (SDS) should be kept. The list may be compiled for the workplace as a whole or for individual work areas. (1)

C. Material Safety Data Sheets (MSDS’s/ SDS’s)

- Manufacturers and importers shall obtain or develop a safety data sheet for each hazardous substance they produce or import. Employers shall have a safety data sheet for each hazardous substance which they use. The manufacturer, importer or employer preparing the safety data sheet shall ensure that the information recorded accurately reflects the scientific evidence used in making the hazard determination. If the manufacturer, importer, or employer becomes aware of any significant information regarding the hazards of a substance, or ways to protect against the hazards, this new information shall be added to the safety data sheet within three months. If the substance is not currently being produced or imported, the manufacturer or importer shall add the information to the safety data sheet before the substance is introduced into the workplace again. (2)

- Chemical manufacturers are responsible for developing SDS. MGE Underground, Inc. must have an SDS for each chemical used. If an SDS is not provided with the hazardous substance, then one must be located.

- SDS must be available for employees to use in each work area. Employees must be able to use SDS when they need them. They must not be kept in a way that keeps employees from using them.

- SDS’s provide you, the employee with specific information on the chemicals you use. The Responsible Safety Officer will maintain a binder with an SDS on every chemical or substance used by MGE Underground, Inc. The SDS will be a fully completed OSHA Form 174 or equivalent. The Responsible Safety Officer will ensure that the shop and each jobsite maintain the appropriate SDS’s for that area. SDS’s will be made readily available to you MGE Underground, Inc. during normal working hours.

- The Responsible Safety Officer is responsible for acquiring and updating MSDS’s/SDS’s. He will contact the chemical manufacturer or vendor if additional research is necessary or if an SDS has not been supplied with an initial shipment. Manufacturers and importers shall obtain or develop a safety data sheet for each hazardous substance they produce or import. MGE Underground, Inc. shall have a safety data sheet for each hazardous substance which they use. All new procurements for the company must be cleared by the Responsible Safety Officer. The master list of chemicals and substances is available for review from.

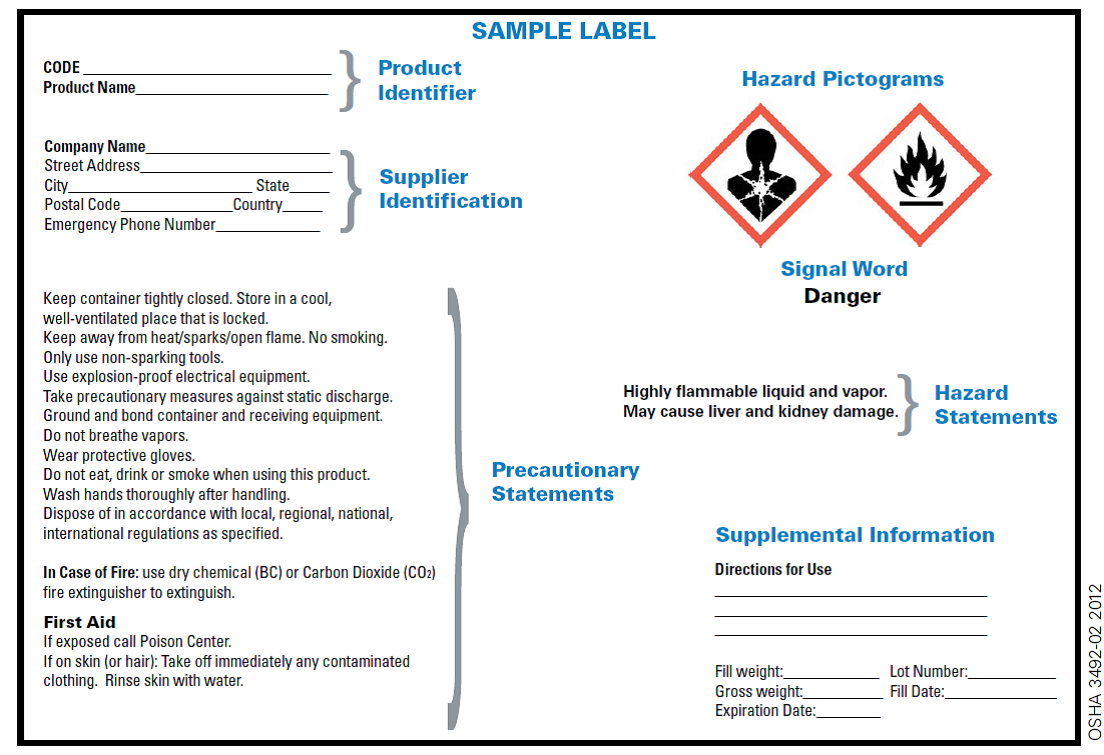

D. Labels and Other Forms of Warning

- The Responsible Safety Officer will ensure that all hazardous chemicals used in the facility and on jobsites are properly labeled and updated as necessary.

- The manufacturer, importer or employer preparing the safety data sheet shall ensure that the information recorded accurately reflects the scientific evidence used in making the hazard determination. If the manufacturer, importer, or employer becomes aware of any significant information regarding the hazards of a substance, or ways to protect against the hazards, this new information shall be added to the safety data sheet within three months. If the substance is not currently being produced or imported, the manufacturer or importer shall add the information to the safety data sheet before the substance is introduced into the workplace again.

- Labels shall be legible, and in English, however, for non-English speaking employees, information shall be presented in their language as well. MGE Underground, Inc. shall ensure that labels or other forms of warning are legible, in English, and prominently displayed on the container, or readily available in the work area throughout each work shift. Labels should list at least the following items:

- The chemical identity.

- The appropriate hazard warnings.

- The name and address of the manufacturer, importer, or other responsible party.

- The Responsible Safety Officer or your immediate supervisor will refer to the corresponding SDS to assist you in verifying label information. Containers shipped from the shop or central office will be checked to make sure all containers are properly labeled.

- If you transfer chemicals from a labeled container to a portable container that is intended for immediate use, no labels are required on the portable container. These portable containers shall not be allowed to remain in any work or storage areas overnight without emptying or labeling to prevent another person from coming in contact with the portable container.

E. Pictograms

- Each container of hazardous chemicals in the workplace shall be labeled, tagged, or marked with either: (A) Product identifier; (B) Signal word; (C) Hazard statement(s); (D) Pictogram(s); (E) Precautionary statement(s); OR product identifier and words, pictures, symbols, or combination thereof, which provide at least general information regarding the hazards of the chemicals, and which, in conjunction with the other information immediately available to employees under the hazard communication program, will provide employees with the specific information regarding the physical and health hazards of the hazardous chemical. Labels or other forms of warning will be legible, in English, and prominently displayed on the container, or readily available in the work area throughout each work shift. Employers having employees who speak other languages may add the information in their language to the material presented, as long as the information is presented in English as well.(4)

F. Non-Routine Tasks

- Before employees perform non-routine or special tasks that may expose them to hazardous chemicals, they are trained on the hazards associated with those chemicals. (3)

G. Training

- Employers shall provide employees with effective information and training on hazardous substances in their work area at the time of their initial assignment, and whenever a new hazard is introduced into their work area. Information and training may relate to general classes of hazardous substances to the extent appropriate and related to reasonably foreseeable exposures of the job. Documentation of safety and health training includes employee name or other identifier, training dates, type(s) of training, and training providers. This documentation shall be maintained for at least one year. (5)

- Anyone who works with or is potentially exposed to hazardous chemicals will receive initial training on the Hazard Communication Standard and the safe use of those hazardous chemicals by the Responsible Safety Officer or a designated representative. This training shall be performed for present workers and for new hires at the time of their initial assignment. The training program may use classroom style training materials and/ or audiovisual aids. Training/information shall include general chemical hazards, how to read labels, and the existing OSHA (Cal/OSHA) HazCom requirements of the standard. Information and training may relate to general classes of hazardous substances to the extent appropriate and related to reasonably foreseeable exposures of the job.

- Employees must be trained on the dangers of the hazardous chemicals they work with. This training will be given when an employee starts work and when a new chemical is used in the workplace. This training may cover types of hazards (e.g. – flammability or carcinogenicity) or specific chemicals. Chemical-specific information must always be available through labels and safety data sheets (SDS). On job sites with multiple employers/companies performing work, information concerning hazardous chemicals in use, methods of providing SDS sheets, methods of precautionary measures to be taken and methods of providing information on labeling systems should be provided.

- The training plan will emphasize these items:

- A summary of the OSHA Standard and details of this written program, including an explanation of the labeling system and SDS’s and how employees can obtain and use the appropriate hazard information.

- Chemical and physical properties of hazardous materials (e.g. flash point, reactivity) and methods that can be used to detect the presence or release of chemicals.

- Physical hazards of chemicals (e.g. potential for fire, explosion, etc.).

- Any operation in their work area where hazardous chemicals are present.

- Physical and health hazards, including signs and symptoms of exposure, associated with exposure to chemicals in the workplace, and any medical condition known to be aggravated by exposure to the chemical.

- Methods and observations that may be used to detect the presence or release of hazardous chemicals by use of monitoring devices, visual appearance or odor.

- Procedures and appropriate work practices to protect against hazards.

- Personal protective equipment required.

- Proper use and maintenance of personal protective equipment.

- Work practices, or methods to assure proper use and handling of chemicals.

- Procedures for emergency response.

- Work procedures to follow to assure protection when cleaning hazardous chemical spills and leaks, or other emergency procedures.

- Where the Hazard Communication Program, any applicable Lists of Chemicals, and SDS’s are located, how to read and interpret the information on both labels and SDS’s, and how employees may obtain additional information.

H. Other Employers/Multi-Employer Worksites

- The items listed below are specific methods for providing other employer information concerning hazardous chemicals at job sites, methods of providing SDS sheets, methods of precautionary measures to be taken & methods of providing information on labeling systems. Where employees must travel between work places during a work shift (multi-job sites), the written program may be kept at a primary job site. If there is no primary, then the program should be sent with employees.

- The Responsible Safety Officer upon notification, will either meet with or have a designated agent meet with other contractors, subcontractors, or any other applicable parties on jobsites to discuss the following items:

- Chemical hazards that may be encountered in the normal course of our work on the premises.

- The labeling system that is in use.

- The protective measures to be taken by our employees.

- The safe handling procedures to be used by our employees.

- The location of the SDS’s.

- In addition, each contractor bringing chemicals on-site must provide MGE Underground, Inc. with the appropriate hazard information on these substances, the labels used, the precautionary measures to be taken in working with these chemicals, and the location of the SDS’s.

- Employees of other employers that may be exposed shall have the following:

- Instructional tutorial on the electronic access and navigation to SDS’s.

- A multi-crew tailboard will be conducted with all employers at the worksite and will review the possible chemical usage with precautionary measures that may need to be taken to protect employees during the workplace’s normal operating conditions and in foreseeable emergencies.

- Tailboard will also conduct a review of labeling system used in the workplace.

I. Additional information

- All employees, or their designated representatives, can obtain further information on this written program, the Hazard Communication Standard, applicable SDS’s, and chemical information lists from the Responsible Safety Officer.